WhatsApp)

WhatsApp)

Manufacturing Of Cement By Wet And Dry Process PPT Ebookinga . PORTLAND CEMENT. They are mixed either dry (dry mixing) or by water (wet mixing). ...

cement manufacturing process and its selection: wet process and dry process cement manufacturing process and its selection: wet process and dry process

manufacturing of cement. ... The three processes of manufacture are known as the wet, dry, and semi dry processes and are so termed when the raw ... Dry process ...

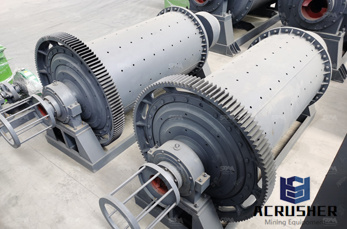

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill.

· Встроенное видео· Wet process. Dry process. Now let us discuss wet process and dry process PROCESS: ... JK Lakshmi Cement Manufacturing Process Duration: 4:12.

Cement Manufacturing Process Civil Engineering. The process is accordingly known as the dry process or the wet process Following is the procedure of manufacturing ...

Other Engineering Assignment Help, Wet process of manufacturing of portland cement, What are Portland cement and its composition? Describe the manufacturing process ...

Manufacturing Portland Cement. The basic ingredients of both the dry and wet processes are the same. By mass, lime and silica make up approximately 85% of .

Portland cement can be made by following two different processes – a dry one and a wet one. The manufacturing process has moved on significantly since bricklayer ...

Wet Process Of Cement Manufacturing, Wholesale Various High Quality Wet Process Of Cement Manufacturing Products from Global Wet Process Of Cement Manufacturing ...

... improvement of kiln efficiency has been the central concern of cement manufacturing technology. ... in a cement kiln; ... The wet process and the dry process ...

Ash Grove Cement and Related Materials (Manufacturing Process) Regardless of whether a cement plant is engineered for wet or dry processing, the raw material mix is ...

Cement project industry. Being one of the basic elements for setting up strong and healthy infrastructure, Cement plays a crucial role in economic development of any ...

Feed Back. Analysis of material flow and consumption in . Abstract. Cement production, which is highly dependent on the availability of natural resources, will face ...

· The wet process of cement manufacturing involves adding water to finely crushed raw material, such as limestone, clay or iron ore, in a proportion of 35 to ...

Manufacture of Portland cement The cements of interest in the making of Dry Process Of Cement Manufacturing Dry ... dry and wet process of cement manufacturing ...

THE MANUFACTURING PROCESS Portland cement is made by heating raw materials rich in oxides of silicon, ... the dry process (used by Golden Bay) and the wet process ...

dry and wet process of cement manufacturing. ... be incorporated into asphalt paving mixes using two different methods referred to as the wet process and the dry ...

Manufacturing the cement kiln. ... a dry process kiln without a precalciner would be shorter than a wet process kiln but longer than a dry process kiln with a ...

What are the differences between the wet and dry processes of a . The wet process of cement manufacturing involves adding water to finely crushed raw material, such ...

Cement manufacturing process | CEMBUREAU. In the second step cement is produced from cement clinker. The first step can be a dry, wet, semidry or semiwet process ...

Methods of cement manufacturing 1 Wet process ... Comparison between wet and dry process ... The raw materials used in the manufacture of Portland cement ...

Define Dry Process, Dry Process assignment help, Dry Process homework help by Manufacturing Process of Cement Tutors

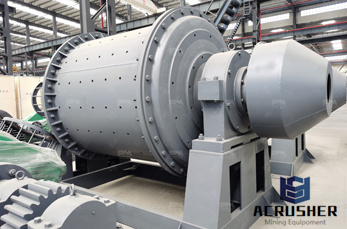

dry and wet process of cement manufacturing. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry.

WhatsApp)

WhatsApp)