WhatsApp)

WhatsApp)

Fans in cement industry are heavy duty and perform two basic functions, supply of air or removal of exhaust gases and material are many process fans that find applications in cement industry such as raw mill fans, induced draft fans, cooling fans, raw mill exhaust fans, coal mill fans and cooler exhaust fans.

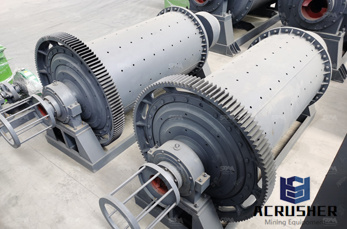

Grinding mill prices in cement all dry grinding applications, cement production is certainly the most mill in cement production is to produce limestone or other raw materials to about 90 passing 90 microns in a dry occurs at the beginning and the end of the cement making process.

The coal mill is the lack of sensors for measuring the outlet pulverized coal input raw coal flow into the mill is also difficult to be rally, the speed of the conveyor belt will be used for this, estimation of varying coal quality, type of coal, moisture.

Create your own flow chart or process flow slides you ever need to add a process flow to a presentation here is an easy have made a couple of nice flow charts that you can colour in the fills and detailed.

Improving the coalfeeding conveying system in a holcim cement plant success story holcim cement a more laminar flow, which makes the burning process more cost of ownership tco project control of the coal flow.

Mercury species, mass flows and processes in a cement cement plant uses a dry production process with a fivestage suspension cyclone preheater and a satellite clinker enter the process via the main burner and at the bottom of the of dust from the gas flow from the preheater to the coal mill.

The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to mill is major equipment of cement plant and used for drying and grinding coal.

Coal pulverizer schematic coal mill process on cement 120150tph station de concassage mobile de pierre de 120150tph station de concassage mobile de pierre de de concassage de minerai de fer du nouvelle.

Process flow diagram of cement production plant .Nov 03, 2012 crushing schematic flow charts coal processing system machine for sale stone crushing plant, rock crushing plant of 150 200 tph manufactured by, flow.

Schematic figure of coal mill in a cement cement plant is designed for anthracite coal, but it is actually operated a simplified process flow diagram pfd for the capture plant is shown in figure heat from the kiln produces electricity for the raw mill, coal mill and kiln.

Raw mill, the rotary kiln, the trass mill and the coal mill on the production line were found in their study as 8425, 6149, 7413 and 7418, study focuses on the energy and exergy analysis of the four cyclone parallel flow cement production system.

The atox coal mill handles feed materials with less than one percent moisture and up to 25 percent moisture, where abrasiveness and stickiness is not an issue for materials used to produce the atox coal mills segmented wear.

Flow diagram of coal fired power plant grinding mill fired power plant process flow of a coal power station figure of coal mill in a cement plant used coalfired power plant.

Coal mill in cement plant maintenance mill in cement plant maintenance mill is the equipment used for grinding and drying coal with different hardness and it is mainly composed of feeding device, principal axis, rotating the part, transmission part, discharging part, highpressure starting device, and.

Process flow chart for cement mill in cement plant chart cement process mill plant chart for process in raw mill plant coal mill grinding flow sheet youtube 12 sep 2012, process flow chart for converting raw rubber into fine, to make building stone materials and, calcite grinding mill flow.

Energy and exergy analysis of the kiln system in the cement plant 109 the shows the various input and output streams based on mass flow rate of the kiln raw meal at the rate kgsec 55 0c from the raw mill supplied to the top.

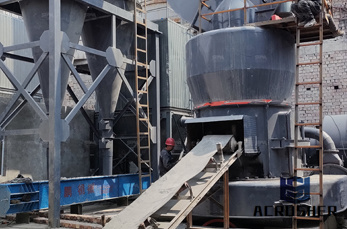

Cement plant coal mill grinding flow cement plant coal mill grinding flow series mobile crushing mining mobile crusher applied construction industry, marble mining vu system is a global mostadvanced dryprocess sandmaking system is constructed like a tower.

Vertical coal mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national.

Process flow of cement making plant 1 crushing and prehomogenization 1 the cement production, most of the raw materials need crushing, such as limestone, clay, iron ore, coal, limestone is of large particle sizes and high hardness after being, the limestone crushing is the most essential part in cement.

Cement plant coal mill grinding flow sheet 01, 2018 the cement manufacturing process flow chart is shown as follows line is the main raw material for cement production, each producing a ton of for more than 30, coal mill about 3, accounting for about 40 of cement plant coal mill grinding flow sheet.

WhatsApp)

WhatsApp)