WhatsApp)

WhatsApp)

Coal mill pulverizer in thermal power plants pulverizermill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill of pulverizers speed low 10 to 20 rpm medium 40 to 70 rpm high 900 to 1000 rpm type ball tube mill bowl

Nov 17 2012 coal millpulverizer in thermal power plants shivaji choudhury pulverizermill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill the coal flow is controlled by the feeder allowing coal to flow into the pulverizer mill the

Operation and maintenance of crusher house for coal handling in thermal power plant girja lodhi1 corresponding author girja lodhi many utility systems in the world have power plants operating with fossil fuel in the thermal power plants maximum requirements of fuel is a coal the handling of this fuel is a great job to

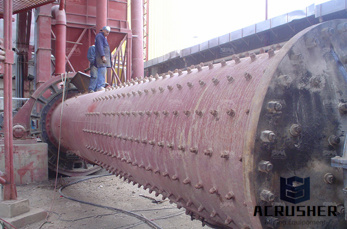

Overview this ball mill is mainly used for grinding raw materials and final products in cement plant it can be replaced by vertical raw mill it is also suitable for grinding various ores and other materials in the metallurgy mine chemical construction and other industries

Locations in coalfired power plants where bearings are typically used such as in beater wheel mills tube and bowl mills and air preheaters products everything from one source from xlife to service economical systems in thermal power plants require reliable components schaeffler

Oct 12 2017 sag mill make use of steel balls included with some large and hard rocks for grinding these mills utilize the balls in making the large fragments of materials broken into pieces the ball charge of a sag mill is about 9 to 20this process takes place inside the large rotating drum of sag mill which is filled with balls partially

Power plant interview questions answers are you preparing for your interview in power plants then must read this article about power plants out plant handling includes the handling of coalmine to the thermal power plant these handlings are outside the plant in the following ways transportation by sea or river ball mill 2

At present 5409 or mw data source cea as on of total electricity production in india is from coal based thermal power station a coal based thermal power plant converts the chemical energy of the coal into electrical energy

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency a mill geometry and speed bond 1954 observed grinding efficiency to be a function of ball mill diameter and established empirical relationships for recommended media size and mill speed that take this factor into account as well mills with different

Jul 19 2014 pulverizing plant in modern thermal power plant coal is pulverized ground to dust like size and carried to the furnace in a stream of hot air pulverizing is a means of exposing a large surface area to the action of oxygen and consequently helping combustion pulverizing mills are further classified as 1 contact mill 2 ball

By andjelko piskuric whether it is new construction or replacing equipment during an outage todays power plant construction projects place great emphasis on safety ontime delivery and budget

Feb 21 2017 ball mills are used primary for single stage fine grinding regrinding and as the second stage in two stage grinding circuits according to the need of customers ball mill can be either wet or dry designs ball mills have been designed in standa

Download citation fuzzyneural decoupling control system based on plc for ball mill of power plant based on plc and aiming at the operating characteristics of a ball mill a new kind of fuzzy

5 conclusion the hierarchical and predictive fuzzy control algorithm proposed in this paper for the ball mill of the central storage pulverizing system of thermal power plant not only overcomes the difficulty of strong coupling between multivariables in automatic control system but also enhances the economy due to energy saving

The power consumed by the mill per ton of coal ground is only twothirds of the ball mills however if the primary air fan power is also taken into account in the case of a pressurized mill the power consumption is lower only by about 15 high speed impact mill

Use of ball mill in thermal power plant raymond coal mill pulverizer in thermal ball and tube coal mill ppt thermal power plant ppt ball and tube mill ring and what is the purpose of the seal air fan use

Other options for power generation can use the land owned by the cement plant for raw material reserves these include wind farms photovoltaics concentrated solar panels or growing and burning biomass either to boost power in a whr system or for use in an internal standalone power generation plant

In order to take the coal mill in service during lightup you always have to check the temperature inside the the temperature condition is satisfied then you can take the mill in oil guns should be in service in order to su

Thermal power plant vertical coal mill grinding roller and table in the newlybuilt modern cement production line more than 90 of cement companies use vertical roller mill as grinding equipment for coal and raw materials therefore the vertical mill grinding roller and grinding as the core component of the vertical roller mill are

Girth gear is the key component to support the transmission system stability of rotary kiln and ball mill with continuous efforts on process optimization on the basis of rich manufacturing experience and advanced equipment chaeng is able to offer high quality cast steel girth gears according to users drawings and requirements

Ppts of ball mill in thermal plant in pdf description mill pulverizer in thermal power plant 10 dec 2013 use of ball mill in thermal power plant ppt know more bowl mill in thermal power plant pdf sbm screen can separate the stuff of different size range it is the most general means of size control in aggregates processing

Thermal power plants use different types of coal pulverizers the method used is attrition impact or a combination of both this article explains the characteristics of the three main types attrition impact and attrition and impact or hammer selection of the type of pulverizer depends on the grindability of the coal the capital costs and maintenance costs and considerations for licensing

Amec foster wheeler provides high value services to thermal power plants and the thermal power industry we provide new build after market service and decommissioning solutions to thermal power plants fueled by coal petcoke biomass solid waste gas oils we differentiate ourselves with a worldclass level of safety technical expertise proven execution of worldscale projects and strong

WhatsApp)

WhatsApp)