WhatsApp)

WhatsApp)

The effect of circulating load and classification efficiency on the performance of ball mill circuits is compared to the effect on hpgr circuits for selection of cut size between hpgr and

Ball size distribution in tumbling mills is commonly used to optimally control the mill product size distribution leaving the mill this is owing to the fact that each ball size effectively break a particular size range in the mill

The high energy ball mill emax combines highfrequency impact intensive friction and controlled circular jar movements to a unique and highly effective size reduction mechanism the grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientation

If it is in wet phase the choice will be mainly towards an agitated ball mill or if the milling is easy and the size reduction expected not too important a colloid mill table 2 particle size reachable for each milling technologies

Furthermore you are able to minimize the feed ball size to achieve higher degree of efficiency of ball grinding which is exceedingly useful for a large amount of grinding this type of rod mills normally feeds balls of less than 15 to 30 mm in diameter to produce 80 product size 500 to 1000m

An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a khd humboldt wedag ball mill on grinding and classification performance of a hybrid high pressure grinding roll hpgrmulticompartment ball mill cement grinding circuit mass balance of the circuit was done by jksimmet steady state

Dec 23 2013 practical 1 title ball milling objective to grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture introduction ball milling is a method used to break down the solids to smaller sizes or into a powder a

The mill product can either be finished size ready for processing or an intermediate size ready for final grinding in a rod mill ball mill or pebble mill agsag mills can accomplish the same size reduction work as two or three stages of crushing and screening a rod mill and some or all of the work of a ball mill

In this study a computer simulation of a suitable matrix notation of the broadbent and callcott grinding model was written first a chromite sample was ground in the laboratory type batch ball mill at different grinding times with different particle size distributions and different capacities

Grinding in ball mills modeling and process control shape of particle size distribution of produc t in a ball mill of the size distribution of ball mill product by modelling grinding

The most important aspect of selecting a sizereduction technology is to know some basic information about the product to be processed feed particle size material characteristics required particle size and desired particle size distribution based on product characteristics only certain milling technologies may be suitable for a given

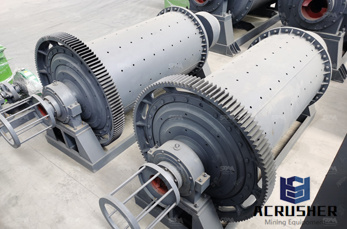

Dec 28 2013 ball mill is the equipment to be used for size reduction it is a kind of grinder used for intermediate or fine grinding ball mill is a metal cylinder which rotates about its horizontal axis the coarse sugar charged along with the metal balls breaks to fine powder by impact of metal balls

Ball size distribution is commonly used to optimise and control the quality of the mill product a simulation model combining milling circuit and ball size distribution was used to determine the best makeup ball charge

N2 in this article alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size distribution were investigated silica ore was used as the test material

Because of its unique grinding motion the xrdmill mccrone is particularly effective for this analytical method the 48 cylindrical grinding elements grind the samples gently via friction the result is a short grinding time with almost no sample loss and an exceptionally narrow particle size distribution

Ball mill product size distributionball size distribution for the maximum production of a ball size distribution is commonly used to optimise and control the quality of the mill product a simulation model combining milling circ

Apr 12 2017 requires less time no cushioning of the product more uniform fine product more capacity low power consumption o vibration mill vibration instead of rotation very fine product faster grinding low power consumption size distribution is narrow o compartment ball mill mill is partitioned by different sized mesh screen

Energy of the moving grinding media into the grinding product the design of a ball mill can vary significantly depending on the size the equipment used to load the starting material feeders and the system for discharging the output product the size of a mill is usually characterized by the particle size distribution in the final

The impact mechanism and long residence times in ball mills combined with inherent inefficiencies of cyclones results in indiscriminate grinding and poor size distributions this leads to slimes generation higher reagent consumption and energy wastage in contrast the isamill produces a different size distribution

Also the uprising velocity in the mill can be controlled by a recycle pump to affect the product size distribution prevent over grinding and reduce the circulating load from the cyclone final product size is a factor of applied grinding power flow rate and slurry density

Ball mill power calculation example a wet grinding ball mill in closed circuit is to be fed 100 tph of a material with a work index of 15 and a size distribution of 80 passing inch 6350

The ground product is discharged from the mill through discharge slots provided in the mill tube through a discharge wall or through the end trunnion the design and setting of the discharge slots or discharge wall determine the grain size distribution of the ground product

The second objective is to provide the correct ball size distribution to grind the finer particles in the composite ball mill feed this objective may necessitate charging a second smaller ball size with the maximum ball size the practice of charging a predetermined ratio of two or more ball sizes to a mill is called rationed ball charging

Ball size as initial charge commercial ball sizes 10 150 mm number size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge for the initial chargin of a mill coghill and devaney 1937 defined the ball size as a function of the top size of the feed ie dv 040 kf

WhatsApp)

WhatsApp)